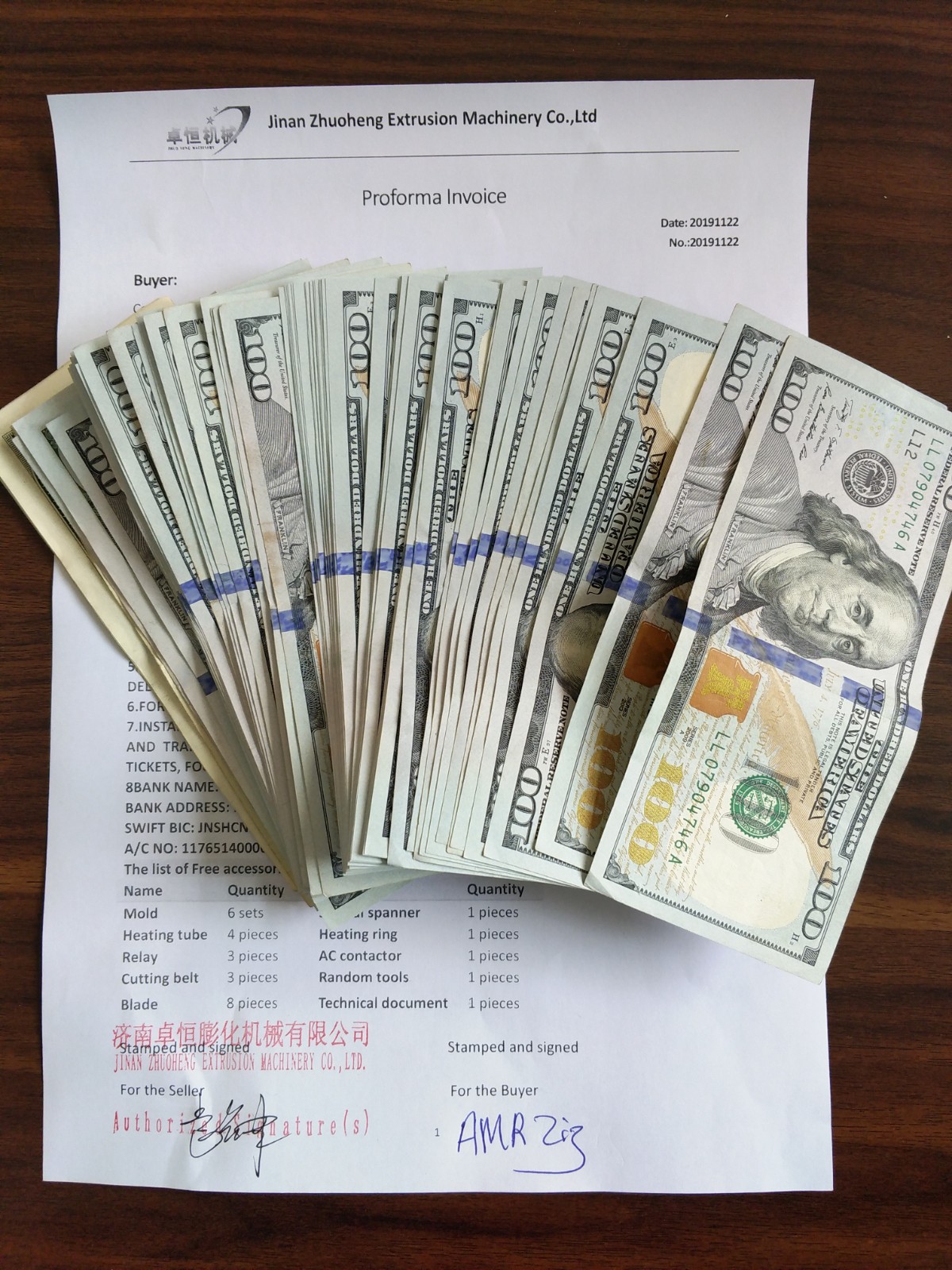

Pedido de los clientes de Egipto para 250 kg / h línea de máquinas de soplado merienda toma de alimentos

Puffed Snacks Production Line is improved and developed based on advanced technology by Jinan Zhuoheng EXtrusion Machinery Co., Ltd.

The machine performance and products quality reach to the most advanced level in the world. This line has features of flexible collocation, extensive applied raw materials, various snack and easy operation.

It is full automatic from mixing, extruding, shaping, cutting, drying to flavoring in one-pass operation. By changing the moulds and process technology, you can produce various shapes of puffing snacks such as rings, flowers, balls, strips, moons, stars etc.

you can produce snacks puffed filling food,fish feed,animal food and soya protein with the same line. All the puffed food taste crispy, easy to be digested. They meet with great favor home and abroad.

"Low cost, high profits" is the suitable generalization of Snack food production line, especially for puff snack food.

Voltage:Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

Puffed snacks food making Machine list

Mixer→ Screw conveyor → Twin screw extruder→ Vibrating machine→ Hoister→ dryer → Hoister → Flavoring line(inclued spaying oil ) → Cooling conveyor

Blend Mixer

Motor: 3.7kw 7.5kw

Model:BF600,BF760

Capacity: 50-60kg/time,(3-5MINUTES)

80-100kg/time, etc.

Material: stainless steel, carbon steel

Zhuoheng's Blend Mixer is adopted the motor connected directly.The stiring wing can tear up that it's easy to clean with low noise.

The mixer barrel is easy to clean and dry that good for food safety

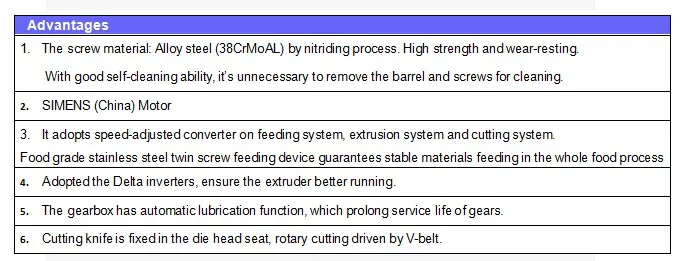

Double Screw Extruder

Motor:ZH65 ZH70 ZH85 ZH95

Motor: 22kw, 37kw, 75kw, 110kw etc.

Capacity: 120-150kg/h, 200-250kg/h,500kg/h...

Material: Screw materials 38CrMoAl

stainless steel, carbon steel

The extruder includes drive system, extrusion system, cutting system, heating system, lubricating system and extraction steam system. Cutting system ,driving system and feeding system controlled by inverter.

Dryer

Type: 5 layers 5 meters, 5 layers 7 meters, 5 layers 12meters, 7 layers 12 meters.

Heating source: electric, gas, steam, oil, diesel.

Material: stainless steel, carbon steel

Oven with hot air circulation system could save more energy.low consumption.

Infrared radition heating tube to heat that can heat and cool rapidly.thermal inertia small,high thermal efficiency

Our company has already exported countries:

Asia { Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan }

Africa { Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe}

Europe { Russia, Bulgaria, Ukraine.Poland }

North America { Canada }

South America { Brazil, Bolivia }

Oceania { New Zealand }

Russia kurstans Sweden East Timor